History of Rayon Fabric: From Discovery to Modern Technological Development

The Beginning of Discovery

Rayon fabric, often referred to as artificial silk, was one of the first man-made fibers developed. Its history began at the end of the 19th century when French scientist Hilaire de Chardonnet discovered a way to make textile fibers from cellulose derived from wood pulp or cotton. In 1884, Chardonnet obtained a patent for a process for making this fiber, which became known as “Chardonnet silk” or “rayon”.

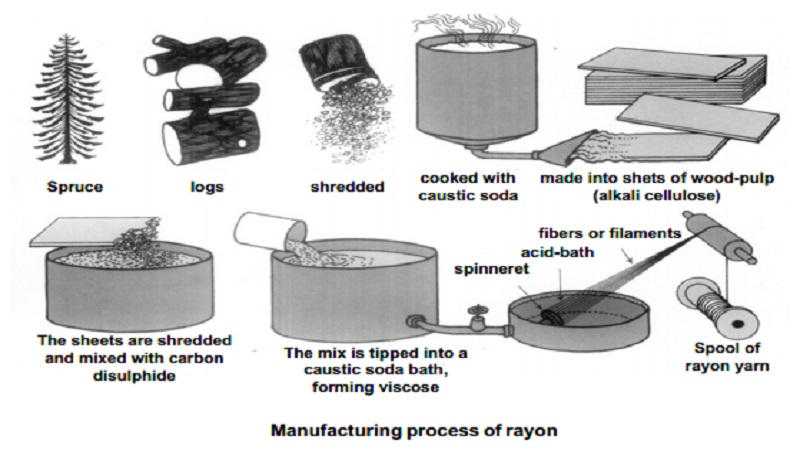

Technical Aspects of Rayon Manufacturing

Rayon is made from cellulose, an organic material found in plants. The manufacturing process involves several important technical steps. First, cellulose is extracted from wood pulp or cotton. Next, this cellulose is processed into a viscous solution through a chemical process involving sodium hydroxide and carbon disulfide, producing a viscose solution. This solution is then forced through small holes in the spinneret to form filaments. The filaments are then collected, washed, regenerated, and finally spun into thread or cloth.

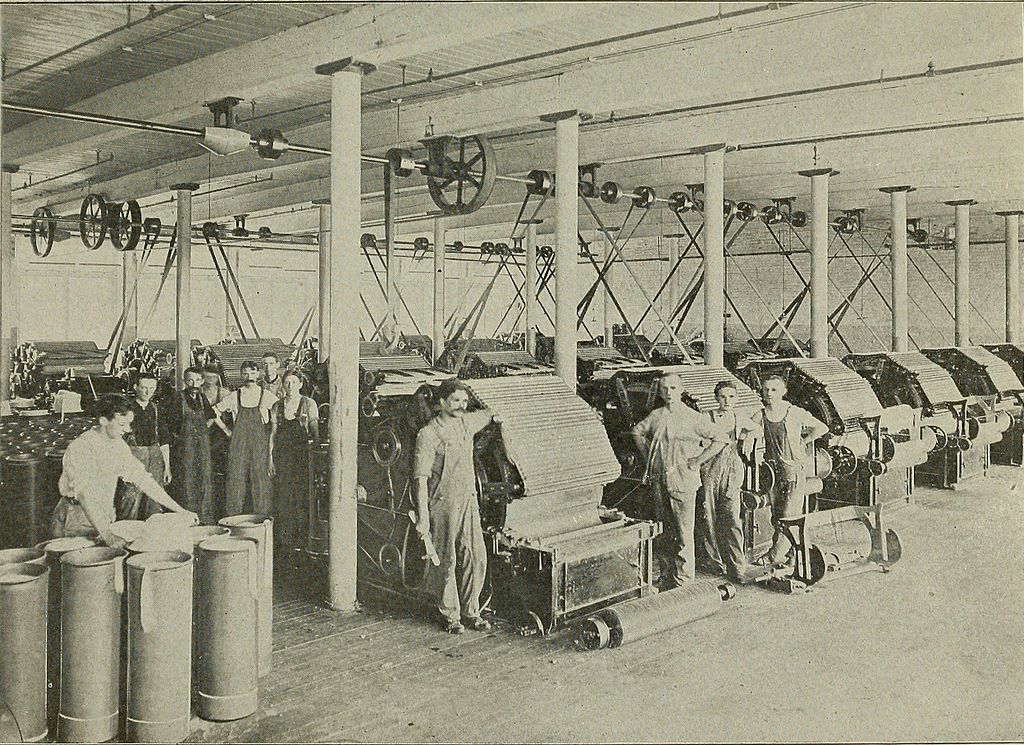

Early Development

In the early 20th century, rayon began to be produced commercially on a large scale. However, the manufacturing process requires dangerous chemicals and often results in a final product that is brittle and easily damaged when wet. This encourages scientists to continue carrying out research and development to improve the quality and safety of rayon production.

Technology and Innovation

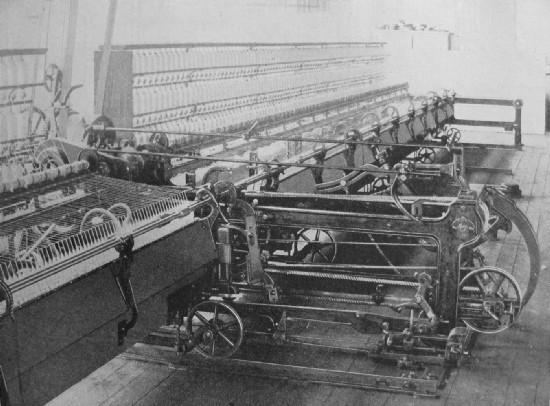

Technological developments play an important role in the evolution of rayon fabric. In 1924, “High-wet-modulus rayon” (HWM) or modal rayon was introduced. This type of rayon has higher strength and better dimensional stability when wet, making it more durable and easy to care for.

Another significant advance occurred in the 1950s with the development of “Viscose rayon”, which used a more efficient and environmentally friendly process. This process involves purifying the viscose solution and using less harmful chemicals. Additionally, developments in spinning technology have enabled the production of rayon with a variety of textures and strengths, making it increasingly popular in the textile industry.

Rayon in the Modern Era

Nowadays, rayon production has reached a higher level with the latest technology. More environmentally friendly manufacturing processes such as “Lyocell” have been developed. Lyocell is a form of rayon made using non-toxic organic solvents that can be recycled, making it a more sustainable option. Additionally, the lyocell production process produces much less waste compared to traditional viscose processes.

Modern rayon has also improved in terms of its physical properties. Rayon is now stronger, more resistant to wrinkles, and more comfortable to wear. This makes it a popular choice in manufacturing various textile products such as clothing, household fabrics, and industrial products.

Conclusion

The history of rayon fabric reflects a long journey from early innovation to the advanced technology we know today. Beginning with the discovery of Hilaire de Chardonnet, technical developments and innovations continue to push the boundaries in rayon production and quality. With an increasingly strong focus on sustainability and efficiency, rayon remains one of the world’s most important and versatile textile materials.

Rayon is not only an important part of textile history, but also an example of how technology can change and improve the way we produce and use everyday materials. By continuing to innovate, the textile industry will continue to develop new ways to make better, safer and more environmentally friendly fabrics.